Construction week 43

The scaffolding is coming down! The Hardie panel on the front, and along the south side still needs finishing, but otherwise – the siding will be finished this week. Major excitement. The drywall will also be finished this week, including the first layer of primer.

Over the weekend, Mark and I worked away on the house. My mom was in town to facilitate this, helping to watch our girls. It’s extremely satisfying to get out and swing a hammer, so to speak. We made great progress as well. We did a massive cleanup of the job site. We’ll be returning unused lumber and selling or giving away the rest on Kijiji. It’s starting to look less like a job site with all the construction material cleaned up and scaffolding mostly down.

We filled another waste bin to the max. The amount of waste our build has generated is something I’m struggling with. Even though most of the materials came from the earth (wood and gypsum), it doesn’t feel good throwing them back in a landfill. There’s a lot of embodied energy in our dumpster. Our friend Gary told me that according to CMHC, the average waste produced by a new home is 2.5 tonnes. That’s about one and a half dumpsters the size we’ve been using. We’ve already filled two and have ordered another one… Our house is no average house, on the other hand. There's a lot more material inside our walls. Considering our walls are two feet thick, and a standard house maybe 8". This is a case for building for the long term. That helps to put me at ease.

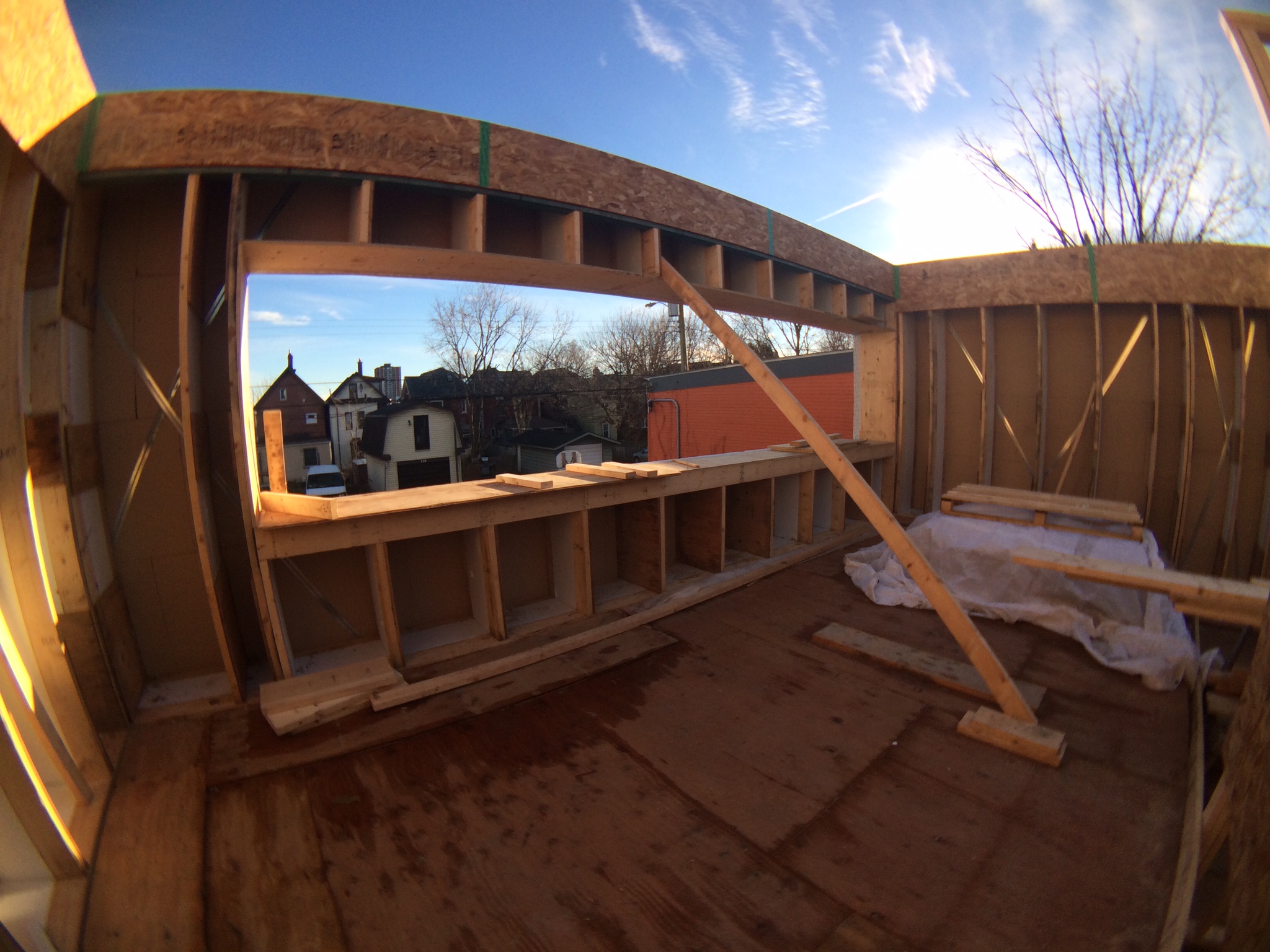

Over the weekend we also started laying the subfloor for our tile guy, who will be starting later this week. We also started on our wood ceiling. Wood ceiling you say? Why yes. We’ve decided to build a slatted wood ceiling. This will add to the sense of discovery we’re hoping to create throughout the house. And will enable us to get clever with our lighting solutions, and hide the mounting tracks.

Tons of coordination efforts this week. Things are shaping up.

Preview of our wood ceiling

Tidy piles of extra construction material

House adornments -- pigeon scaring tactics seen to be working!