Construction weeks 33 & 34 – plumbing, hvac and more

manifold system

plastic in the walls

Wow, it’s been a couple weeks since I’ve provided an update. The house has been relatively quiet with only one or two people working at a time. That has since dramatically changed…

Nathan, from Ackland Plumbing, has finished the first rough-in phase for plumbing. We’ve got spiffy (BPA-free) breathable supply pipes running through the house, and a purple one which supplies the grey water. He was explaining to me how, just 10 years ago, a different kind of plastic pipe was getting installed in Canadian houses, one which does not breathe and where water stagnates and becomes unsafe for drinking. Insurance companies will not insure these houses and lawsuits are being filed against the building code. Lesson learned: what seems like a good idea today, may very well prove to untrue tomorrow. And wet things need to breathe, trapped moisture is the enemy of building. I digress. Back to our house.

Nathan managed to carefully maneuver all supplies and drains in and between our open floor trusses and walls. The design of our house helped to facilitate this, with Mark stacking all the plumbing and electrical to one side of the house, over the mechanical room. (This poses absolutely no risk Myles btw (comment from previous post), it’s actually a really clever thing to do when building because all utility runs are minimized in terms of materials and labour). We’ve received numerous compliments on Nathan’s handiwork and it passed the plumbing inspection no problem-o. He’s as excited as we are to have a neat and tidy mission control in our mechanical room, where we’ll go copper for added ‘wow’ factor. Good stuff.

wood fibreboard clads the house until the siding gets installed overtop

the cardboard box phase

Speaking of passing inspections, we also passed our building envelope inspection. Hooray! We were nervous about this one because we weren’t sure how the inspector would feel about forgoing the traditional Tyvek weatherproof house wrap for our wood fibreboard. The wood fibreboard is more common in Europe and is not often seen on our side of the pond. Mark provided specs to the building inspector and explained it to him. We’re fortunate to have an experienced and open-minded official. But there’s no doubt to anyone walking through or around our house that it’s a well-built, thoroughly considered house.

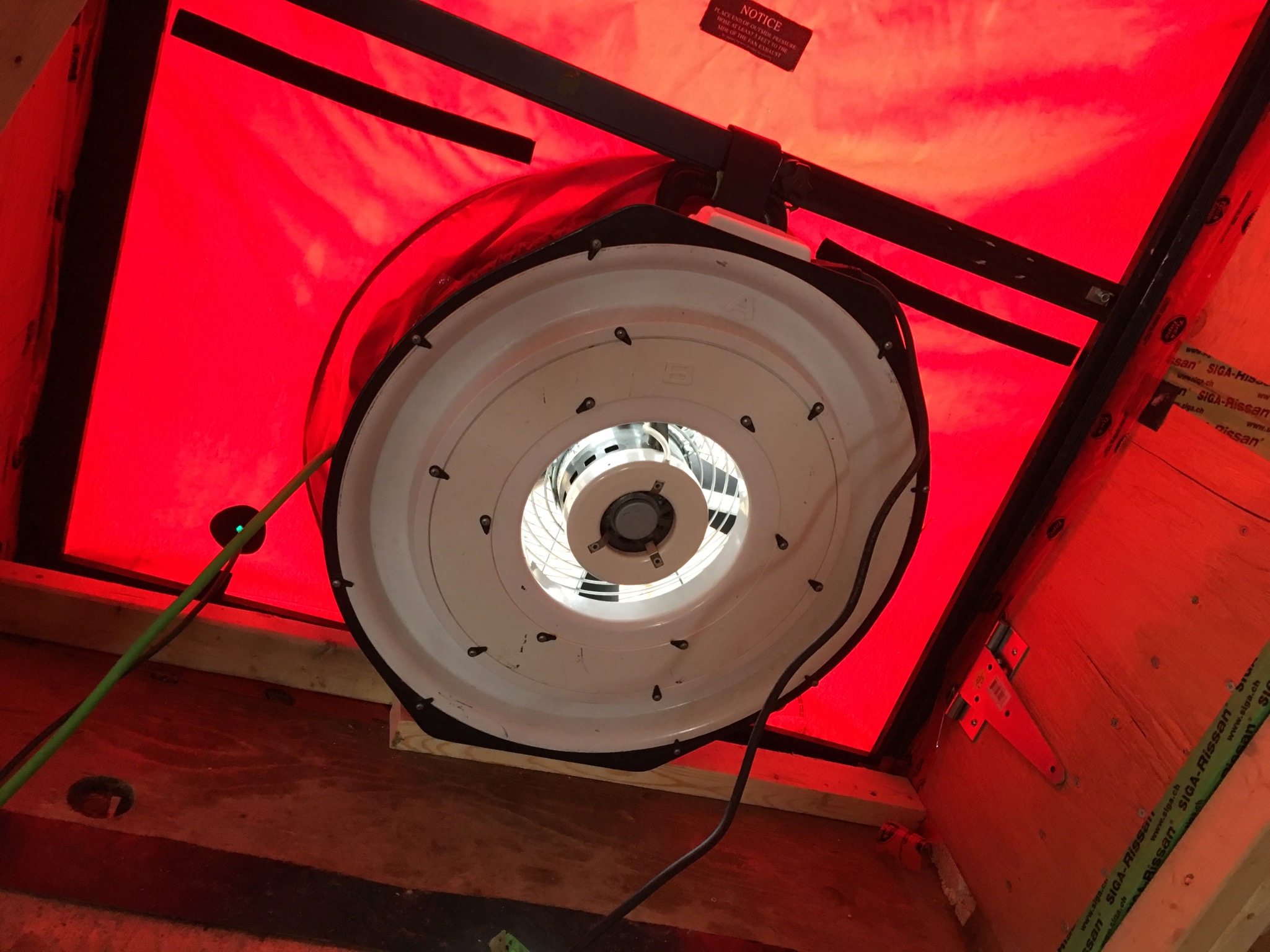

And back to the mechanical room. Hans from Pinwheel Builds met with Mark and dropped off our new Zehnder HRV and heat exchanger along with coils of flexible plastic pipes, which are to be our house’s air ducts for circulating what little heat we require. It’s a pretty groovy system. We won’t have any gross floor ducts, bulkheads or metal work in our house. All you’ll see are small 8” diameter circles mounted to the occasional wall and ceiling to circulate air. Mark went over his plan with Hans and has started installing the ducting himself. Unboxing the parts was better than Christmas for Mark. He was so excited.

parapet roof

new carhartts

From here on out, Mark will be spending as much time as possible working on the house himself. He bought himself a spiffy new pair of Carhartt overalls for the task ;) In addition to starting the ducting, he finished the parapet (a fancy word for structural railing) on our flat roof, cleaned up the front and back yards, and hosted another tour. This last one saw around 30 people who joined as guest of Malcolm Isaacs, who runs the local Passive House courses and is a director of the Canadian Passive House Institute.

brown ash cabinets

On the backend, we ordered our kitchen. Another hooray! Finally. There were a few back-and-forths during the homestretch, which prolonged the process, but were key for getting the details ironed out. We’re really excited about it. We ended up going with Astro Design Centre and have had a great experience working with Dean Large. He ‘gets’ us, in terms of design, and was able to add real value to our design experience, which we really appreciated. Astro also had the finishes we liked the most, at the best price. For example, a gloss white was the same cost as a matte white (typically gloss costs more). And we don’t want any hardware, we want recessed handles (a no hardware look typically costs more). We went with the Astro house brand in white gloss for all the cabinets except those on the backside of the island. The backside of the island faces the living area. For these cabinets we chose a sand-blasted (i.e. textured) brown ash. Haven’t ordered our countertops yet. That’s next.

Following suit, we made a decision on our wood flooring and placed the order. We’ve decided to go with white ash from the Wood Source. The same white ash that the city of Ottawa has felled throughout the city to thwart the Emerald Ash Borer. It will be sympathetic to the island wood. We also decided to order some extra wood for the sloped ceiling, which spans our open space, over the master bedroom and loft. A slatted wood ceiling will allow for clever lighting hacks. We’ll be able to hide much of the hardware behind the wood so that we only see what we want to see and can get away with using less expensive fixtures at no aesthetic compromise. It will also look incredibly beautiful. It’s a win-win.

As alluded to earlier, the house is buzzing again this week. Siding has begun amongst other exciting things. Do stay tuned and lookout for another Mark Periscope. He broadcast just today. And hope you’ll join the next house tour!